An fmea is analytical technique employed by a team as a means to assure that to extent possible potential failure mode and their causes have been consider and address.

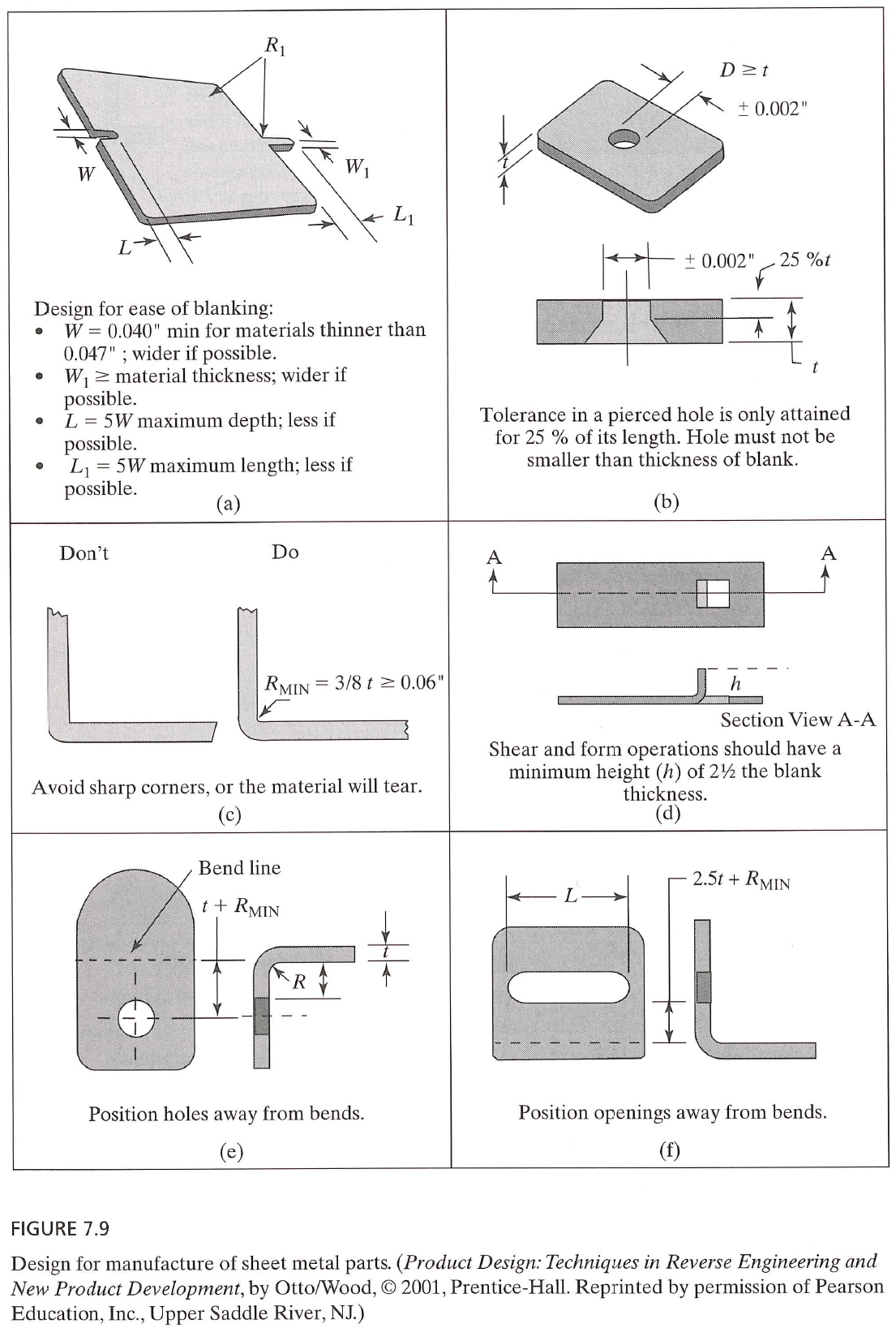

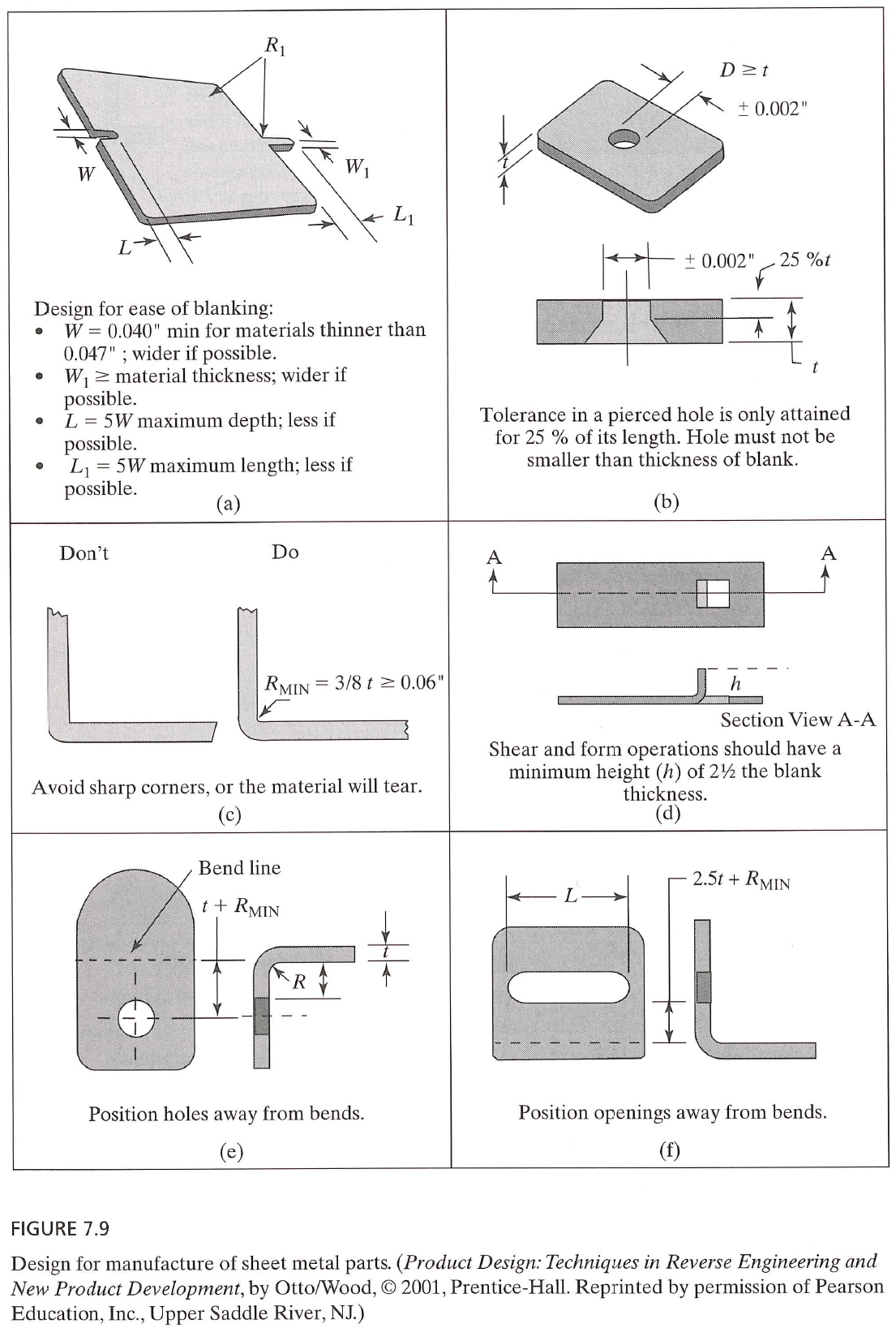

Fmea sheet metal.

Fmea of sheet metal components free download as pdf file pdf text file txt or read online for free.

This paper will give a brief view of rules and flow of fmea to apply it in sheet metal industry.

Failure mode effect analysis fmea risk priority number rpn.

An item is the focus of the fmea project.

Failure mode effect analysis fmea risk priority.

This paper will give a brief view of rules and flow of fmea to apply it in sheet metal industry.

Failure mode keywords.

For a system fmea this is the system itself.

For a process fmea this is usually one of the specific steps of the manufacturing or assembly process under analysis as represented by an operation description.

For a design fmea this is the subsystem or component under analysis.

Fmea scales for severity occurrence detection severity scale for failure modes effects s cale of 1 least severe to 10 most severe for each effect occurrence scale for potential root causes s cale of 1 least frequent to 10 most frequent for each root cause minor rank 1 low rank 2 3 moderate rank 4 6 high rank 7 8 very high rank 9 10.

General benefits of fmea the general benefits of fmea include.

2003 hradec nad moravicí 1 the fmea method used in process approach to the quality management of sheet metal process marta migalska technical university of częstochowa department of management.

An fmea is analytical technique employed by a team as a means to assure that to extent possible potential failure mode and their causes have been consider and address.

Design process and machinery fmea s to address the objectives and requirements of the selected type of fmea.